How Do Grease Traps Work?

Commercial kitchens and similar establishments produce a lot of fats, oils, and grease (FOG). These need to be kept out of main drainage and sewerage systems so they don’t pollute the environment. While we simply rinse off our oily pans at home down the drain, it is illegal to let large amounts of FOG into main drains, which is why businesses are required by law to install grease traps.

If you’re thinking of opening a new business or getting a grease trap installed, then you’re going to need all the information about how it works, the best type and size you should get, and best practices for proper maintenance. Read on below to learn more about grease traps:

How does a grease trap work?

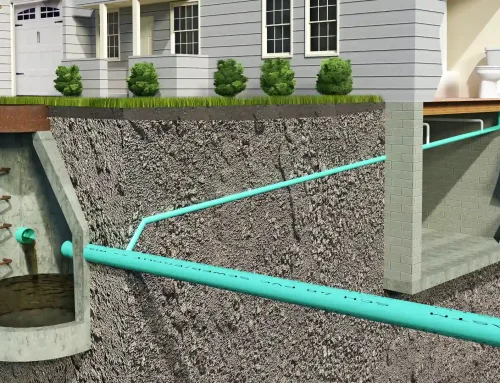

In the most fundamental sense, grease traps separate FOG, dirty water, and food debris layers. This is done by cooling the water that flows through the flow control valve on its way to the grease trap. As the water cools, the fats, oils and grease solidify and float to the top of the trap, while food scraps and other debris sink to the bottom. A grease trap’s outlet pipe which drains FOG and debris-free water is generally located in between these two top and bottom layers so they don’t flow through with the water into the sewers.

What type and size of grease trap should you get?

Grease traps come in a variety of types and sizes.

There are three main types of grease traps: passive hydromechanical, automatic, and gravity grease traps. Passive systems are the most common as they are cheaper and easier to install. Automatic grease traps skim out FOG on a programmed schedule so operators don’t need to check grease levels or manually clean them. Gravity grease traps are larger, in-ground versions of a passive grease trap, and need to be pumped out on a regular basis by a specialised service company.

Smaller grease traps are generally designed to connect to individual sinks while larger ones (such as gravity grease traps) serve larger establishments that produce more FOG. Choosing the right grease trap size depends on the nature of your business, and the smaller your trap, the more often it will need cleaning. It’s important that your certified contractor takes the right factors into account to ensure you get the right grease trap installed.

How often should a grease trap be cleaned or pumped out?

Here’s the general rule of thumb: as soon as the top grease layer and the bottom debris layer occupies 25 per cent of the grease trap’s space, then it’s time for a clean or a pump-out. Grease traps need a deep layer of water to make sure they work properly, and too much FOG or debris will only clog up your grease trap.

Streamline Environmental & Drainage: Grease Trap Cleaning Wizards

Streamline is proud to say that we make grease trap cleaning easy. Our grease trap cleaning service will keep your drains flowing smoothly.

The Streamline team is available 24/7 for all your grease trap cleaning needs. Contact us today at 0800 001 150 to have a vehicle dispatched to your location!