Project Description

VALENTINES RE LINING

Case Study

Challenges & Achievements

Trenchless repair of a drain with tight access and various sections to repair.

Working around traffic and high flows and multiple users on the line.

Challenges & Achievements

Overview

After repeated issues with blocked drains, we were called in to analise the cause of the blockages.

Being a high flow drain due to high production from the large valentines restaurant, it was important to keep the drain flowing at all times.

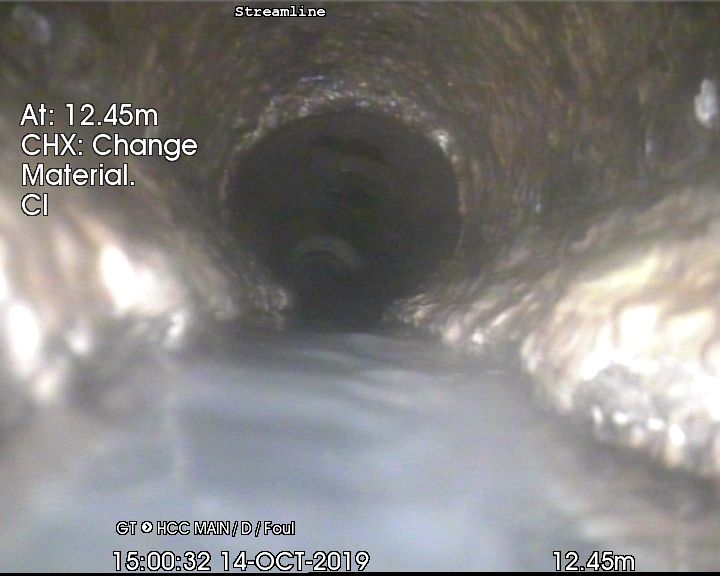

A CCTV inspection revealed sections of cast iron mixed with earthenware on a 47m long section of drain.

This drain ran under a building, and the surrounding area had a lot of services and high traffic flows.

Tuberculosis on the sides of the cast iron sections was casing the drain to block, as the corrosion was reducing the pipeline diameter and creating a jagged edge which toilet paper was catching on.

We offered a price on lining the sections as a long term fix, which was accepted, and work was asked to start asap.

The Project

The first aspect we had to consider was the rough edge and reduced diameter. During the planning stages we identified this as a key issue. We also knew access would be an issue, as we had initially only had access from the grease trap outlet, which was too tight for lining.

A manhole was installed further down the line on top of a inspection which had the wye connection from the grease trap and toilets, this would provide us access from which to line and jet.

The first part of the project was to mill the rust of of the pipe using a chain flail, this was done after hours to keep disruption down. We used Jet01 hooked up to our turbine chain flail and only milled each section of cast iron, so we would not damage the earthenware sections.

This opened up the pipe, giving us the tolerance for putting the liner in, it also gave us a firm surface for the liner to bind to.

The project had a total of 21m to line, 7 short sections and 1 x 12m section. And we started with the short sections at the top.

All was going smoothly until we came to the long section, where our long packer got stuck due to access issues, and the patch set in the line while we were extracting it.

Using a combination of UHP, milling cutter and flexshaft, we were able to remove the liner and proceed with the project.

We had expected that the job would be difficult due to the length of the line, but this did put behind schedule.

After some planning, we got back into the project, and had the 12m section lining in a few days.

Despite some issues, the drain never overflowed during the project, and we ended up with a quality result giving a long term fix to a complicated solution, and our investment in equipment paid off when things did not go as planned.

The Outcome

The result was a no dig repair

The extension of the life of the pipe

No overflows or spills during the project

FREE QUOTE

Do you need help with waste water maintenance? Fill out this form to get in touch.