What is Hydro Excavation?

Hydro excavation has emerged as a ground-breaking method revolutionising how we dig, excavate, and uncover buried utilities. This innovative technique combines the power of pressurised water and advanced vacuum technology to remove soil and debris precisely and safely. As industries increasingly recognise the need for efficient and non-destructive excavation, understanding hydro excavation has become paramount.

Gone are the days of relying solely on traditional excavation methods that often involve heavy machinery, manual labour, and the inherent risks of damaging underground utilities. Hydro excavation offers a safer, more precise, and environmentally friendly alternative that has gained significant traction across various industries.

In this blog post, we delve into the basics: what is hydro excavation, how does it work, and does it have any advantages over traditional methods? Join us as we uncover the power of hydro excavation and how it is transforming how industries approach excavation projects.

The Basics of Hydro Excavation

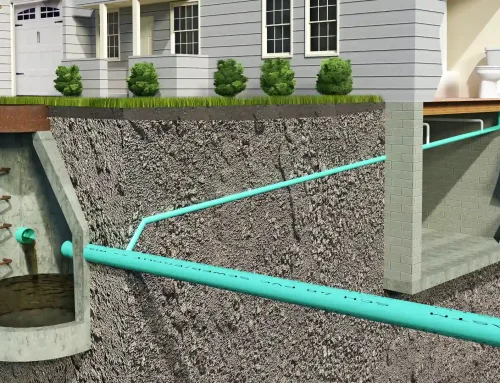

Hydro excavation is an innovative method that uses pressurised water and powerful vacuum technology to remove soil and debris precisely. Its primary purpose is to expose underground utilities, such as pipelines, cables, and wires, safely and non-destructively without the risk of damage.

Unlike traditional excavation methods that rely on heavy machinery, manual labour, or mechanical digging tools, hydro excavation offers a more efficient and controlled approach. Pressurised water breaks up the soil, and a high-powered vacuum suctions the resulting slurry into a debris tank, ensuring minimal disruption to the surrounding area and reducing the risk of accidental utility strikes.

The equipment used in hydro excavation typically consists of a specialised truck or trailer-mounted unit that houses a water tank, a high-pressure water pump, a vacuum system, and a debris tank. This equipment provides precise control over the excavation process, allowing operators to target specific areas and remove soil accurately and precisely.

How Does Hydro Excavation Work?

The hydro excavation process begins with a specialised hydro excavation truck or trailer-mounted unit.

The operator identifies the excavated area and determines the underground utilities’ location. Then, using a high-pressure water pump, pressurised water is directed through a hose fitted with a specially designed nozzle. The nozzle emits a concentrated jet of water that breaks up the soil, creating a slurry mixture.

Simultaneously, the vacuum system comes into play. It uses a powerful suction force to extract the excavation site’s slurry, soil, and debris. The debris is then deposited into the debris tank, separating it from the water.

The operator maintains control and precision throughout the process by adjusting the water jet’s pressure, flow rate, and distance to ensure accurate excavation. The process allows for careful soil removal while avoiding damage to underground utilities.

The pressurised water effectively breaks up the soil, making removing it easier, while the vacuum system swiftly and efficiently extracts the slurry mixture.

Key Advantages of Hydro Excavation

Hydro excavation offers many advantages over traditional mechanical excavation methods, making it a preferred choice for many industries. Key advantages include the following:

Safety

Enhanced safety is one of hydro excavation’s main advantages. Unlike mechanical excavation methods that involve heavy machinery and manual labour, hydro excavation eliminates the risks of accidental utility strikes, cave-ins, and injuries from equipment operation. The precise control provided by pressurised water and vacuum technology minimises the chances of damaging underground utilities, ensuring the safety of workers and reducing potential liabilities.

Damage prevention

Pressurised water allows for precise and controlled soil removal, enabling operators to uncover buried utilities without causing any harm. Visually exposing the utilities before excavation greatly diminishes the likelihood of accidental strikes to pipelines, cables, or wires. Hydro excavation’s damage prevention aspect prevents costly repairs and helps maintain the integrity of critical infrastructure.

Environmental advantages

Unlike mechanical excavation, which can cause excessive noise, vibrations, and dust, hydro excavation creates minimal disturbance to the surrounding environment by utilising pressurised water and a vacuum system.

Additionally, the water used in the process is often recycled and reused, reducing water consumption and minimising environmental impact. Overall, hydro excavation aligns with sustainability goals and promotes responsible excavation practices.

Limitations to Consider

Hydro excavation is highly effective in loose or sandy soil but may face challenges with compacted or rocky soil. The depth and size of the excavation area also need evaluation, as hydro excavation may have limitations in reaching deeper or narrow spaces.

Additionally, consider factors such as weather conditions, site accessibility, and project timelines to ensure the feasibility and efficiency of hydro excavation for a particular project.

A main limitation of this process is the potential for water saturation in the excavation area. If not managed properly, excess water can lead to soil instability or create muddy conditions, causing project delays.

The presence of underground utilities that are difficult to detect or accurately locate may require additional utility locating techniques or coordination with utility companies to ensure safe excavation. Moreover, hydro excavation may require access to a water source and proper disposal methods for the excavated slurry, which may pose logistical challenges depending on the project location.

Traditional mechanical excavation methods, such as backhoes or manual digging, may be more suitable for certain projects where the soil is not sensitive, or the presence of utilities is well-documented. These methods may also be more cost-effective for smaller or simpler excavation tasks. On the other hand, hydro excavation excels in situations that demand precision, safety, and minimal disruption, especially when working around sensitive utilities or in congested areas. One can determine whether hydro excavation or an alternative method is optimal by comparing the specific requirements and project objectives.

The Future of Hydro Excavation

Hydro excavation continues to evolve with emerging technologies and advancements that promise exciting possibilities for the future. One notable trend is the development of more efficient and powerful hydro excavation equipment. Innovations in water jet technology, such as rotating nozzles or adjustable pressure settings, are enhancing the precision and effectiveness of the excavation process.

Additionally, improvements in vacuum systems, including increased suction power and filtration capabilities, optimise debris removal and reduce downtime for equipment maintenance. Advancements in remote control and automation are also streamlining operations. These advancements allow operators to control hydro excavation equipment safely and enhance overall efficiency.

The potential for improvement in hydro excavation is vast. As technology advances, we can expect increased automation and the integration of artificial intelligence to enhance the excavation process further. Developing eco-friendly and sustainable water recycling systems may also become a focus, reducing water consumption and waste generation. Moreover, new applications for hydro excavation are on the horizon, including exploring archaeological sites and environmental remediation. These advancements and expanded applications promise to transform hydro excavation into an even more versatile and indispensable method for various industries.

Utilise Hydro Excavation with Streamline

Hydro excavation provides numerous advantages over traditional excavation methods, including enhanced safety, damage prevention, and environmental friendliness. However, it is important to consider factors such as soil type, excavation area size, and project requirements before opting for hydro excavation.

Despite some current limitations, the future of hydro excavation looks promising, with ongoing advancements in equipment technology and the exploration of new applications. As industries continue to recognise hydro excavation’s efficiency and non-destructive nature, its role in transforming excavation projects will likely grow. If you’re interested in hydro excavation for your project or want to learn more, contact Streamline Environmental & Drainage today. Alternatively, you can enquire about our other liquid waste services, including grease trap cleaning, drain inspection, and much more.